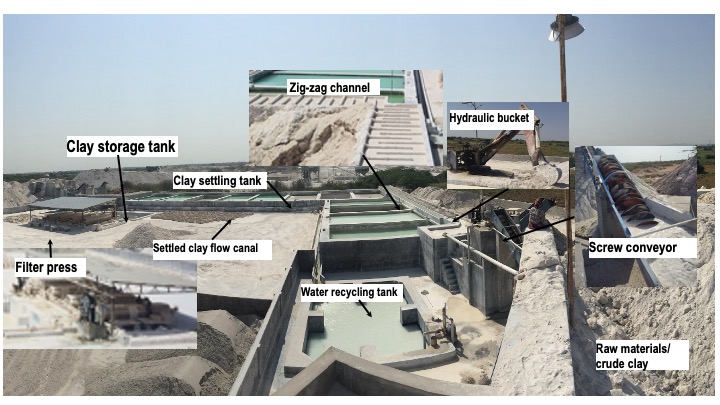

Levigated Clay: Levigation Process Steps of Crude Clay

The crude clay excavated from the ground consists of clay, sand, small stones, organic material,…

20 Tests to determine Clay Quality and Applications

Clays are used in different industries and processes based on their property requirements. Therefore, clay…

What is Than Clay / Grey Than Clay / Washed Than Clay?

Fire clay that is mined in the region of Thangadh, Gujarat is known as Than…

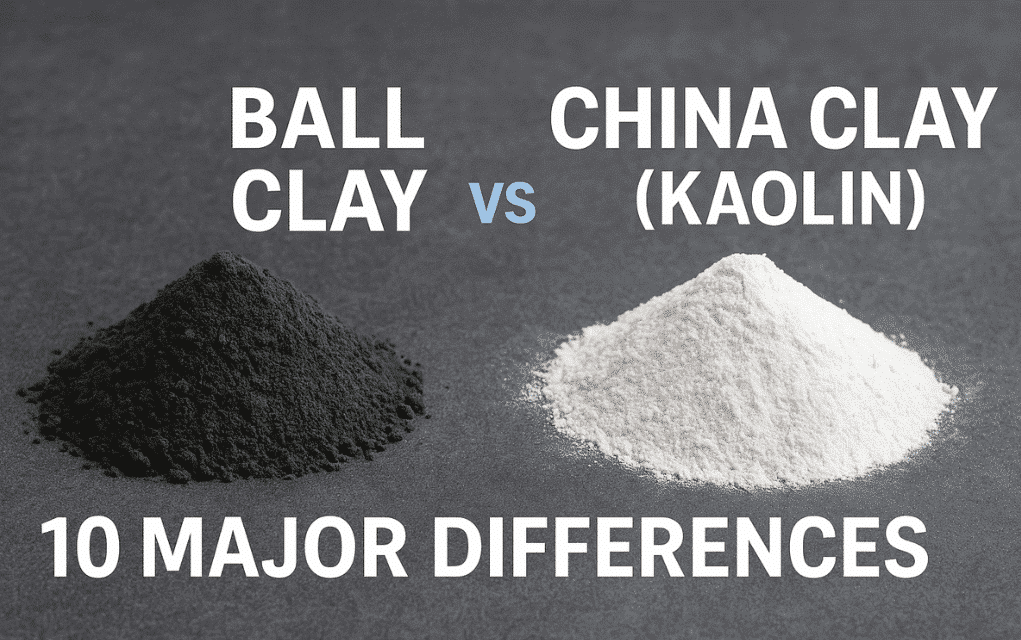

Ball Clay vs China Clay (Kaolin): 10 Major Differences

Clay is the major contributor to the dry and fired properties of the ceramic body.…

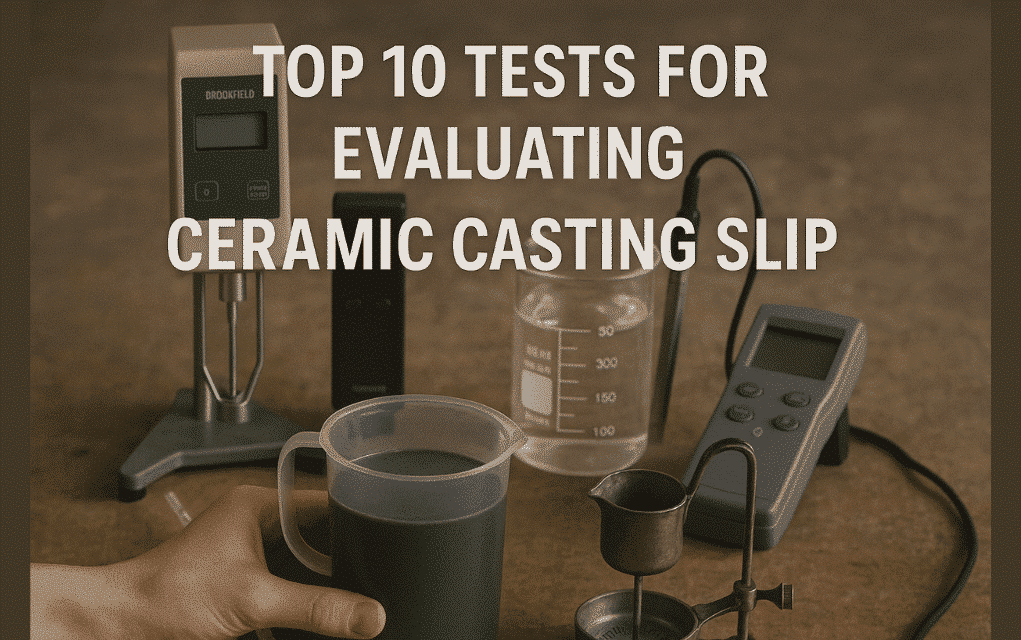

10 Tests for Evaluating Ceramic Casting Slip

Slip casting is one of the traditional forming methods used in the ceramics production process.…

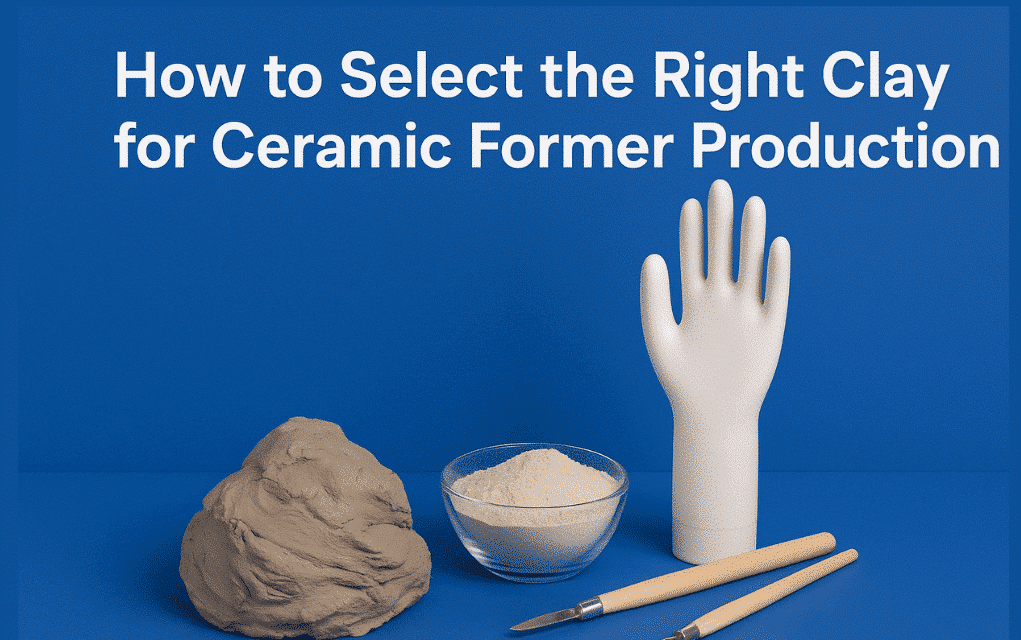

How to Select the Right Clay for Ceramic Former Production

Selecting suitable clay for the ceramic formers is very crucial because around 50% of the…

Top 20 Ceramic Associations around the World

Ceramic associations are vital to the growth of the industry, and they provide a platform…

How to Formulate Ceramic Formers Slip? Properties, RM & Formula

A perfect formulation of ceramic formers body or slip ensures that the material meets all…

20 Common Defects In Ceramic Formers Manufacturing

We have listed 20 common defects in ceramic former manufacturing. Defects increase rework, energy consumption,…

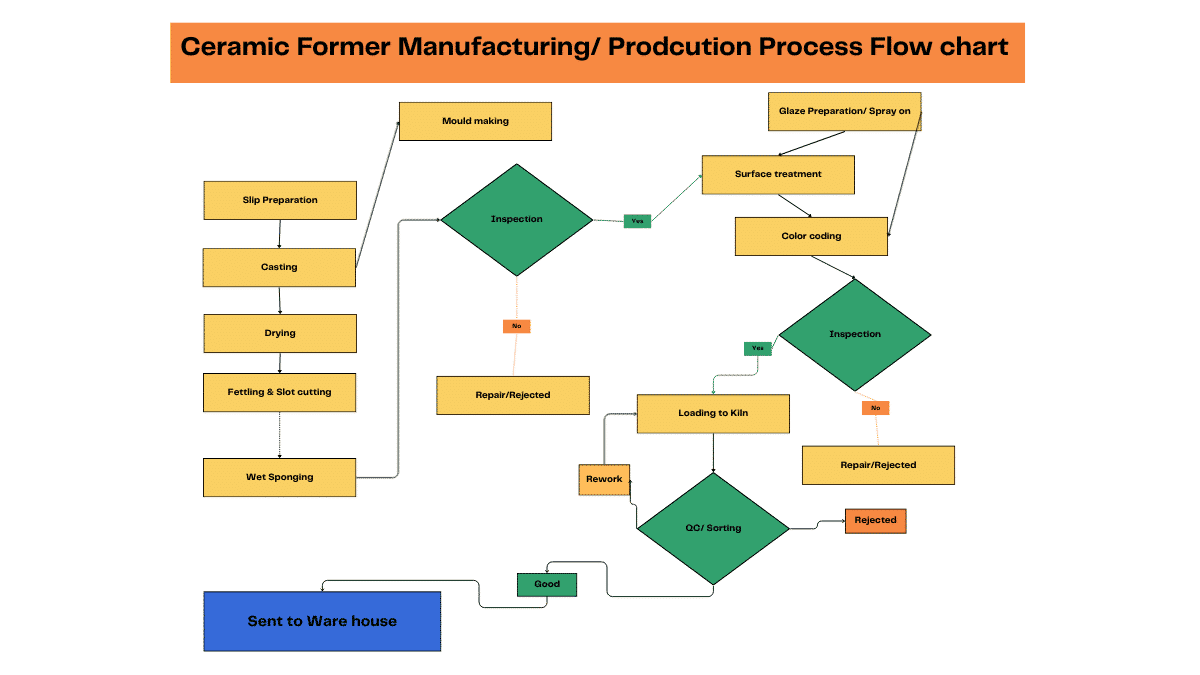

Ceramic Formers Manufacturing/Production Process

Ceramic formers production/manufacturing process consists of the following 10 steps. [toc] 1. RM & Slip…

20 Essential Equipment For Sanitaryware Laboratory

Multiple pieces of equipment and tools are necessary for the sanitaryware laboratory to conduct day-to-day…

30 Key Components of Sanitaryware Factory Documentation

Documentation is the initial phase of launching a sanitaryware factory. It's crucial that this documentation…

9 Major Cost Elements in Sanitaryware Production

In the sanitaryware industry, the production cost is calculated based on the cost per kg.…

Investment Guide for Setting Up a New Sanitaryware Factory

A well-researched proper budget is required for any new sanitaryware factory to sustain market competition…

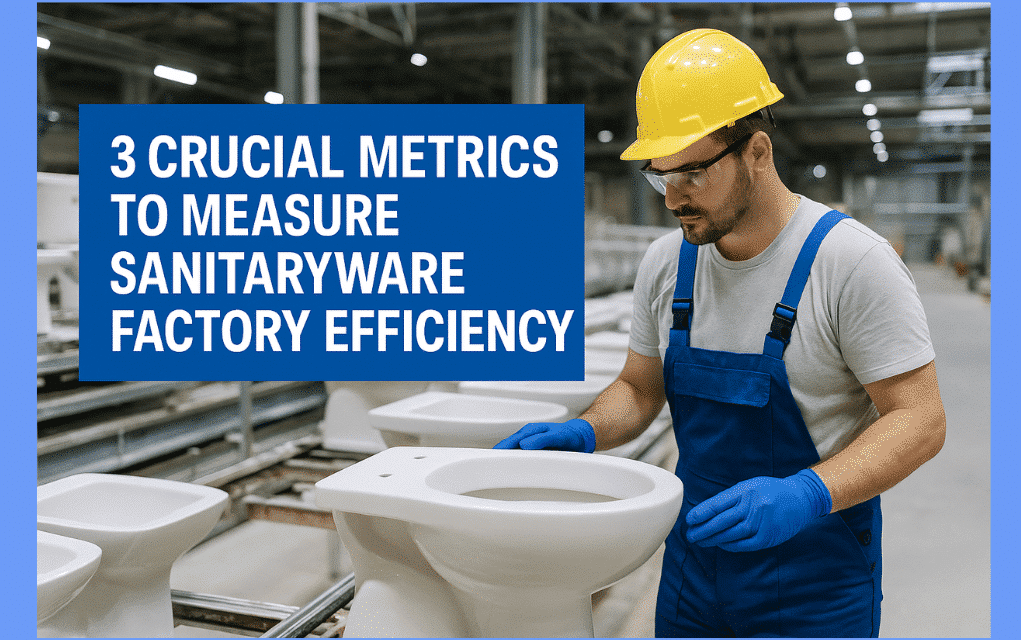

3 Crucial Metrics to Measure Sanitaryware Factory Efficiency

While Analyzing efficiency of a sanitaryware manufacturing factory, focusing on a only 3 key metrics…

7 Essential Yields Every Sanitaryware Manufacturer Must Track

Different yields serve as crucial indicators of performance, pinpointing where improvements can be made and…

High-Pressure Casting Technology in Sanitaryware

In this article we are going to Look about High Pressure Casting Machine used in…

Top 100 Sanitaryware Manufacturers in Morbi (India)

Here is the list of top best 50 Sanitaryware manufacturing company(manufacturers) in Morbi. Get their…

Ball Clay: Processing, Properties, Uses & Formulas

Comprehensive Guide to Ball Clay: Properties, Composition, Processing, and Applications Ball clay is a kaolinite-rich…

China Clay: Definition, Processing, Properties & Uses

Find the china clay definition, processing, properties & uses here. China clay, also known as…

Top Sanitaryware Manufacturers in Gujarat (India)

Here is the list of Top sanitaryware companies in Thangadh, Gujarat, India. We have listed…

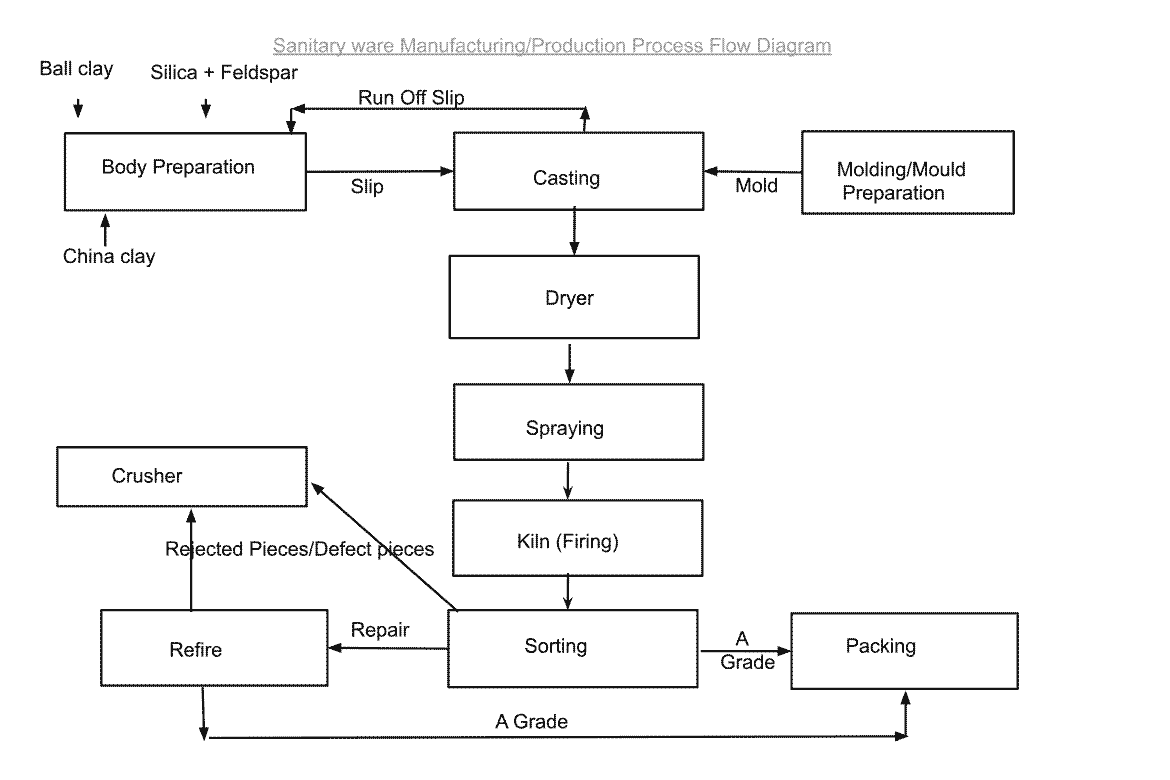

Sanitary ware Manufacturing/Production Process

Sanitary ware manufacturing/production process consists of 10 steps from Body preparation to Packing. [toc] sanitary…

Top Sanitaryware Manufacturers in Thangadh (India)

Here is the list of Top sanitaryware companies in Thangadh, Gujarat, India.We have listed out…

Battery Casting Machines in Sanitaryware Industry

In this article, we will see detailed information about battery casting machine used in sanitaryware…

Top Sanitaryware Manufacturing Companies in Turkey

Find below the list of sanitary ware manufacturing companies in Turkey. Turkish ceramic sanitaryware are…

How to Start a Sanitaryware Manufacturing Factory

In this article, we are going to see what are the points needed to consider…

Sanitaryware Glazed by Dipping Method

This video was taken at 1921. This video shows how Glazing was done by dipping at…

Crawling Defect in Sanitaryware: 10 Causes & Solutions

Crawling is a well-known defect encountered daily in ceramic sanitaryware production, akin to issues like…

Manual vs Carousel vs Robot Glazing in Sanitaryware Industry

Glazing stands as a pivotal stage in the sanitary ware manufacturing process, often integrated with…

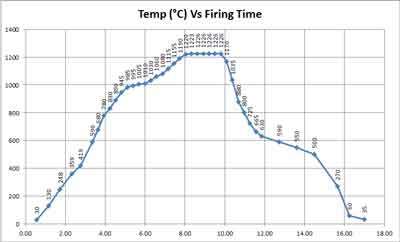

Physical & Chemical Reactions During Sanitaryware Firing

Firing is the final and important process in sanitaryware production. Firing of sanitaryware can be…

10 Effective Ways to Reduce Sanitaryware Production Cost

The sanitary ware production industry is experiencing rapid growth, intensifying competition. To thrive in this…