What is a water closet?

The water closet is a ceramic sanitary ware product which is used as a toilet. This kind of toilets is more hygiene and easy to clean. The Toilet which is designed to sit is known as water closets. Usually Sitting height of the water closet will be 400mm(16 inches) from the ground. This sitting height 400 mm(16 inches) is not going to be always same, but it is a standard height preferred when designing a water closet toilet. Water closet will be attached to a tank for flushing the waste. That tank can be made by ceramic or plastic materials. Mostly the plastic seat and cover will be connected with the water closets. The water closet is also known as a European water closet. The minimum life of the seat cover will be around 10,000 usages by using polypropylene or polyurethane toilet covers or seats made.

In the above picture, you can see the water closet set in a restroom. This Picture consists of 1) Water closet 2) Seat & Cover 3) Plastic tank connected with WC.

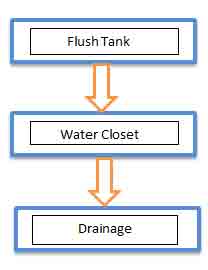

WC connections:

Below you can see the flow diagram of WC connection.

WC will be connected to the drainage using rubber water sealant(gasket), and it will be fixed in-wall or floor using fittings. Then the water tank will be connected to the tank by a plastic pipe and the water pipeline connected with the water tank. At any time someone flushes the tank, water will be flushed out through the drainage. And the water will be filled in a tank through a water pipeline. A float switch will be available in the tank, which always helps to maintain a water level. Usually water tank capacity will be 6 litres to 10 litres.

Production of Water Closet:

Water Closets were manufactured in sanitary ware industries. The water closet is ceramic material fired at above 1200 degree Celsius (2192 Fahrenheit). Material used to produce the toilets are sand, feldspar & clay. Desired toilet design will be built using plaster of Paris mould. Once the design is made, it is dried. Then it is required colour glaze is sprayed on the piece and sent to the firing. Once firing finishes, the toilet will be tested and sent to packing.

Fittings & Accessories for Water Closet:

When you buy a WC normally, some Fittings & Accessories will be available with the package. They are,

1) Seat Cover with fittings

2) Floor mount Fittings or Wall mount fittings

3) Flushing mechanism with Tank.

4) Water sealant(Gasket).

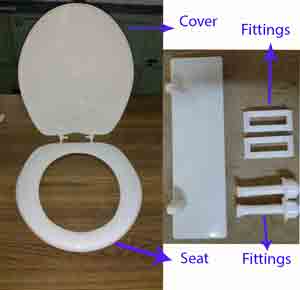

Seat & Cover With fittings:

A seat and cover will be available with the water closet. Accessories will also be available with the box.

Floor mount Fittings or Wall mount Fittings:

These fittings are used to mount the closet in the wall or floor. Below is the picture of Floor mount fitting from a closet box.

Various Designs of Water Closets:

Water closets different designs are,

1) Standard water closet.

2) One-piece water closet.

3) Two-piece water closet.

4) wall-hung, WC. 5) ‘S’ trap WC. 7) ‘P’ catch WC.

You can find top Branded water closet manufacturers

Water Closet quality tests:

After production, WCs undergoes some quality checks. It must pass the test otherwise that wc is not suitable for use. Some of the tests are, FLUSH TEST

The water closet should satisfy the requirements of test. These tests are:

1. TOILET PAPER TEST ‘

2. HOLDING CAPACITY

3. SMUDGE TEST 4. BALL TEST

a) Double Ball test

b) Fifty Ball Test

These tests shall be conducted by conducting the water closets to low – level cistern conforming to I.S 7714, 1984 or I.S 7281, 1994. A cistern shall be 30 cm. and the water closet is conducted to the cistern by 40mm normal diameter flushing/pipe.

TOILET PAPER TEST: The water closet shall be filled with water to its normal water seal level and charged with six pieces of usual toilet paper or polythene sheet thickness of 0.05mm approximately and Size of 150X115mm and loosely crumbled. It shall then be repeated four times and the ware should discharge the full charged paper.

HOLDING CAPACITY TEST: The water closet when scaled up the outlet and vent (if fitted) with water tight seal shall be capable of holding not less than 10 litres of water between the normal water level and the highest possible water closet as inserted.

SMUDGE TEST: The hole of the interior surface of the water closet to 40 mm below the flushing, the rim are smudged with quartz powder with contrasting colour passing through 1.18mm I.S sieve and shall be flushed immediately after flushing, There should not be any smudge left below.

BALL TEST: 1. DOUBLE BALL TEST: The balls should be made of non-absorbent material. The relative density of the ball should be between 1.075 and 1.080. The diameter of the ball shall be 43+/ 0.5mm place the balls shall be discharged in the normal manner. 2. FIFTY BALL TEST: Fifty balls of non-absorbent, having a mass each of 3.7+/-0.1gm. And a diameter 20+/-0.1mm shall be dropped into the water closet and flushed. Repeat the test for 5 times. A minimum of 8% of all balls should be fused out in the tests. You can refer more sanitaryware lab tests taken in Lab here.

Advantages of Water closets:

Good for elder people and sick people to use. Physical active required is less. Easy to clean. More hygiene compared to squatting pans.

Disadvantages of Water closets:

More water consumption compares to conventional methods. Flushing requires 6 litters but in conventional methods, less water is required. The research found that using WC gives more knee problem in future.

Acronym related to Water Closet:

Water closet: WC European Water closet: EWC Wall Hung Water closet: Wall hung WC One-piece water closet: One-piece WC Two piece Water Closet: Two-piece WC Coupled Water closet: Coupled WC.

I have a question about: Water Seal in a Commode. I understand the purpose and admire the simplicity, effectiveness, and low cost.

However, I am trying to design an “odorless toilet” (and here I’m not speaking of sewer gases back-flowing into the bathroom) which requires an additional path, parallel to the existing path used by the liquid and waste. This additional path uses a fan to suction tainted air and force it down thru this added path to the main drain. Presumably I must use a solenoid-actuated air valve to provide access to the drain and also, when not in use, the valve must serve the same function as a water seal, namely to block the back flow of sewer gas.

What back pressure must this valve be capable of blocking ?

Is there anything else besides back-pressure in trying to duplicate the function of a Water Seal?

[…] water closet consists of three parts; they are bowl, pedestal and a tank. Foundation of the toilet is to give […]