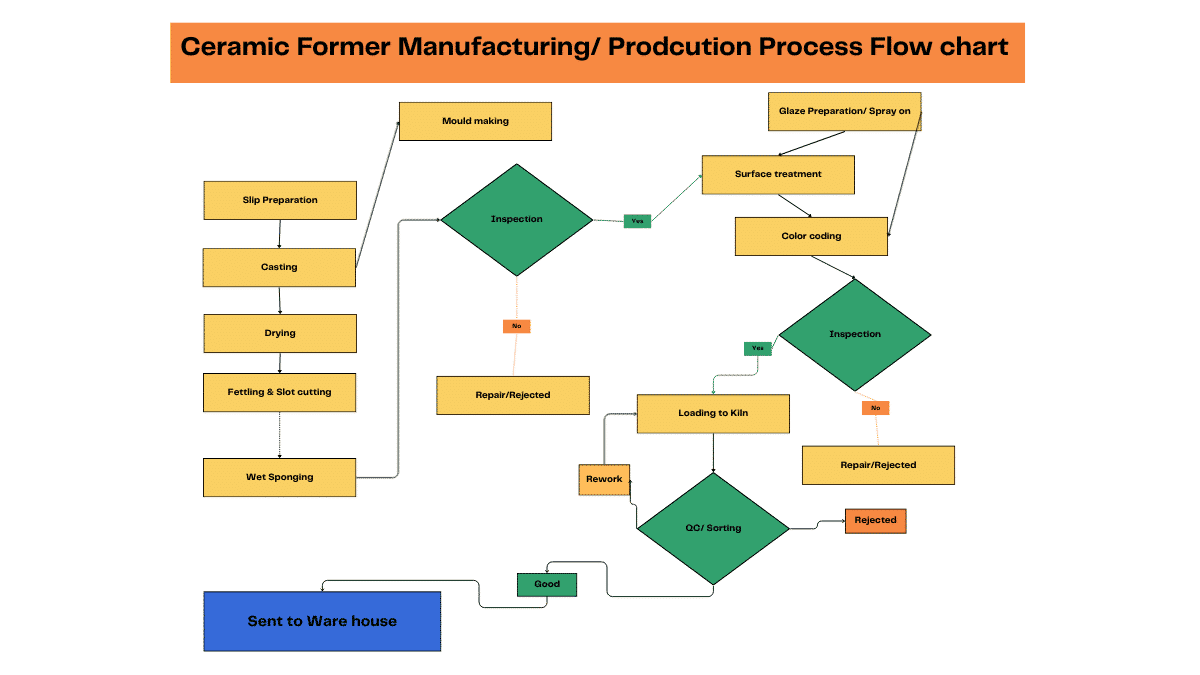

Slip casting is one of the traditional forming methods used in the ceramics production process. The slip is prepared and cast in the mold, which may be made of plaster of Paris or resin. Then excess slip is unloaded, and the formed cast piece is demoulded, dried, finished, glazed or unglazed, and finally fired to get the product. This method is used in the production of sanitaryware, ceramic glove formers, and other related items.

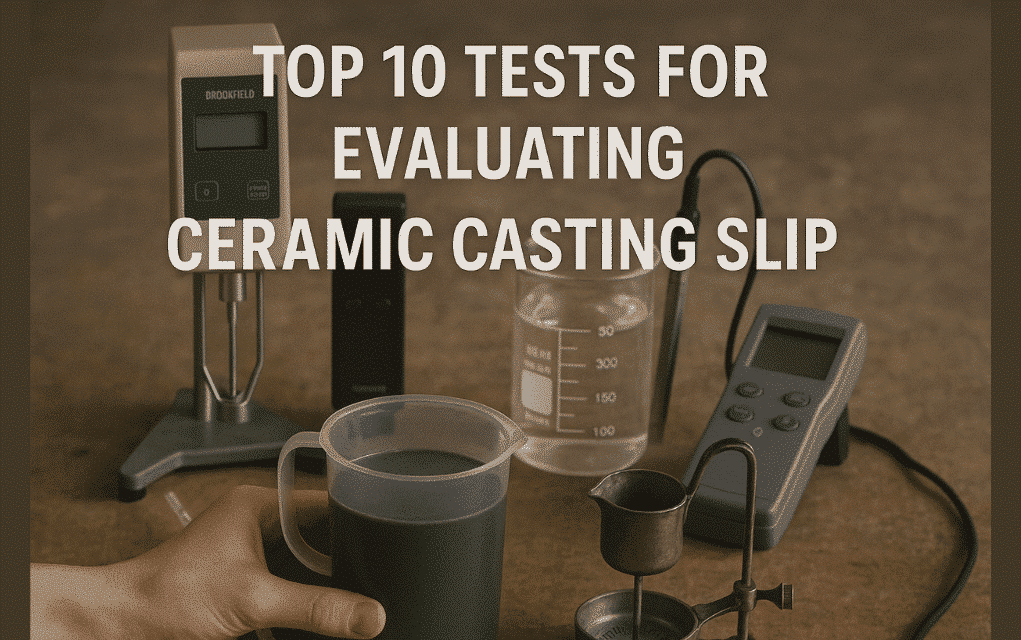

Optimum slip properties help the slip perform better with fewer defects and a stable production process. By evaluating the following properties of ceramic slip, one can gain a better understanding of the slip behavior in the production process. The top 10 tests for evaluating ceramic casting slip are,

Density: (Specific Gravity)

Density of the slip controls multiple behaviors of the casting process, like cast rate, drying behavior, and slip unloading behavior. The density measurement of the ceramic slip is done by a pycnometer or density cup. In general the density of the casting slip is between 1.75 gm/cc to 1.85 gm/cc. The density is adjusted based on the complexity of the casting, the thickness required, and unloading/drying behavior.

Fluidity:

Fluidity is the measurement of slip flow behavior, which can be measured using a torsion viscometer, Ford cup, and Brookfield viscometer.

In a torsion viscometer, the flow of ceramic slips will be between 320 and 345 degrees in most slip casting processes. In a torsion viscometer, the first reading is fluidity.

In the Ford cup, the flow varies based on the Ford cup used; in general, for the ceramic slip flow measurement, Cup 4 and Cup 5 are used.

In the Brookfield viscometer, the first reading is the viscosity of the slip. The reading will vary based on the spindle number and the RPM.

The number varies based on the method of measurement, but the important thing is to find an optimal fluidity/viscosity for the process and maintain it to keep the process stable and efficient.

Thixotropy

Thixotropy controls the slip unloading behavior, cast rate & drying behavior of the slip. For better drying and unloading, a low thixotropy slip is preferred. This property is measured by a torsion viscometer, a Brookfield viscometer, and even a Ford cup.

The torsion viscometer is widely used in ceramics for thixotropy measurement. It is used to find 5-6 minutes of thixotropy. This method is more accurate than the thixotropy method using a Ford cup.

More efficient thixotropy can be found using a Brookfield viscometer. The Brookfield viscometer aids in understanding viscosity variations over time, even for extended periods.

Residue:

Residue of the slip can cause defects like dunting and pinholes and also reduces the MOR of the body. Slip can be tested at 80#, 100#, 120#, 200#, 325#, and 350# to understand the residue at different mesh sizes. Mesh size is selected based on the process requirement.

Cast Rate:

Cast rate is the thickness of the slip formed in the given time. The cast rate is tested for 10 minutes, 30 minutes, and 60 minutes to understand how the slip thickness forms.

Cast rate is found using two methods: one is using a plaster of Paris mould & the other is the Baroid method. Casting using a plaster mould is much simpler and can vary based on the environment; this helps to mimic the casting area environment, so using this method in a cast shop will give a better idea. Baroid will avoid all the variables like mould, environmental temperature, and humidity. This method is useful to have for reading for the laboratory.

Shrinkage:

Shrinkage is the measurement of size reduction during the process of production. There are two types of shrinkage: one is green shrinkage, and the other is fired shrinkage. Shrinkage happens from the mould opening to the firing and is known as green shrinkage; the difference between before firing and after is known as fired shrinkage. Green shrinkage happens due to moisture removal from the body, and fired shrinkage happens due to vitrification & LOI (organic compound burn-off & removal of chemically combined water). Total shrinkage of the ceramic slip will be around 12%.

MOR:

MOR is a measurement for understanding the strength of the body. There are two types of MOR: green MOR and fired MOR. Green MOR helps to understand the dried body strength, and fired MOR helps to understand the strength of the body after firing. This testing is done by casting a round or square bar and testing it in a three-point contact stress load. MOR is calculated using the span length, diameter, and the peak load at which the bar breaks.

Warpage:

Deformation that happens during the firing process is called warpage. The warpage is found by placing a 220 mm square-shaped bar in between two refractory supports before firing and measuring the deformation after firing. Low deformation helps reduce defects in the body, like bad shape.

Water Absorption:

Water absorption testing is a method of finding the degree of vitrification in the ceramic body after firing. The lower the water absorption, the better the vitrification. The fired ceramic piece is first weighed, then immersed in boiling water, removed from the water, and weighed again after the surface water has been wiped off. By using the formula, the water absorption is found. A properly vitrified body will have less than 0.5% of water absorption.

Drying Behavior:

There is no standard test to measure the drying behavior of the slip. It is an observation test. After casting in the plaster mould or Baroid cake, the cast piece is allowed 30 minutes or 60 minutes, then it is pressed, and it is observed how much stiffness there is in the cast piece.

Key Takeaway:

The above 10 tests will reveal key properties of the ceramic slip. Based on the results, process parameters or the formulation can be changed to fit the product requirement.

Post Comment