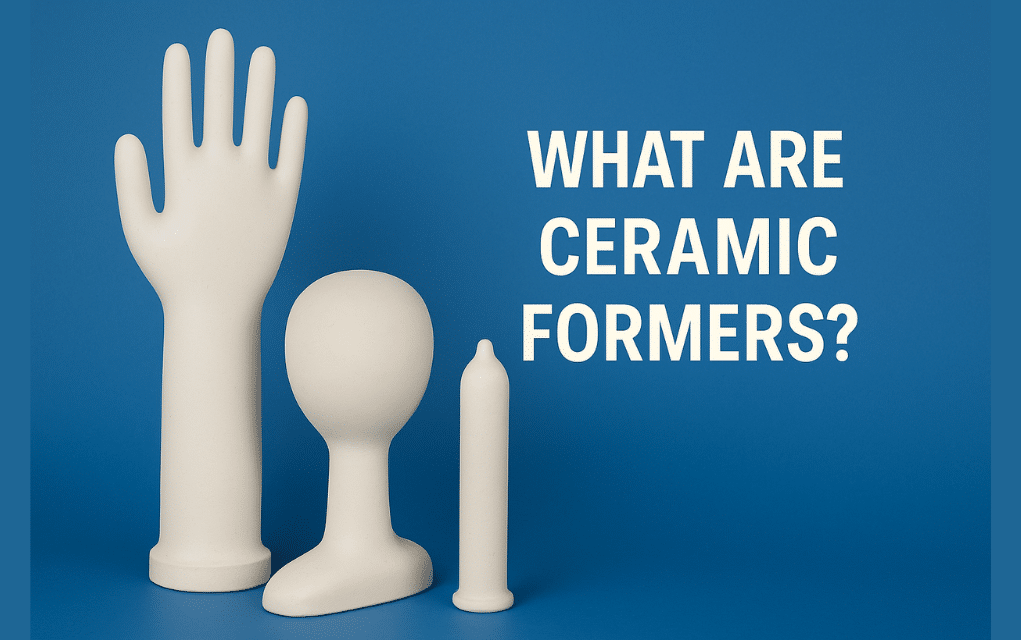

Ceramic formers are ceramic wares that are casted into required shapes and sizes, then fired at temperatures up to 1250°C. This fired ceramic pieces are used as a dipping molds in the production of various rubber products.

In gloves or other product manufacturing process, this ceramic formers is connected to a chain conveyer and moves into the molten latex, nitrile, or rubber at around 140°C. A thin rubber layer forms on the ceramic surface, which is then cooled, blown and stripped off. After every cycle, the formers are cleaned by dipping into chemical bath.

Applications of Ceramic Formers

The most common know ceramic former type is glove formers. Other applications types are shoe formers, ballon formers, condom formers and etc.

Advantages of Ceramic Formers

Ceramic formers are widely used over metal formers due to the following reason and the properties.

• Their performance and cost benefits:

• Low water absorption (<0.5%) so longer shelf life.

• High thermal shock resistance, this helps formers to withstands repeated heating and cooling cycles during production usage.

• Ceramics are chemical resistance with helps in the cleaning cycles without much erosion.

• Ceramic are cost-effective and durable compared to metal formers.

Surface Finishes of Ceramic Formers

Depending on product requirements, manufacturers offer different surface finishes:

• Glazed

• Unglazed

• Sandblasted

• Patterned (spray-on finish)

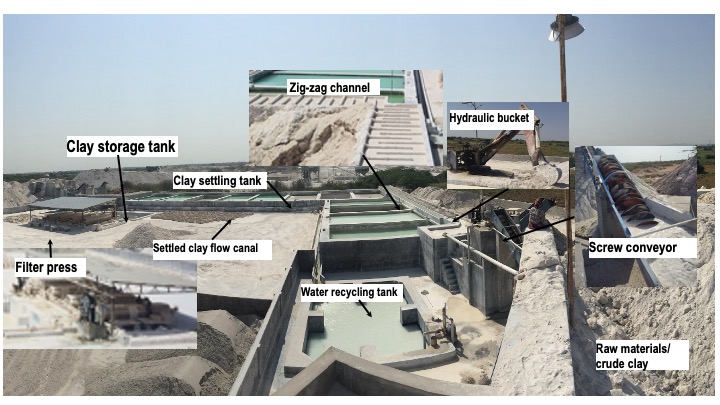

Raw Materials Used

Just like traditional ceramics , ceramic formers are made with clay(Ball clay, china clay), quartz, calcined alumina and Flux (Mostly Nepheline syenite).

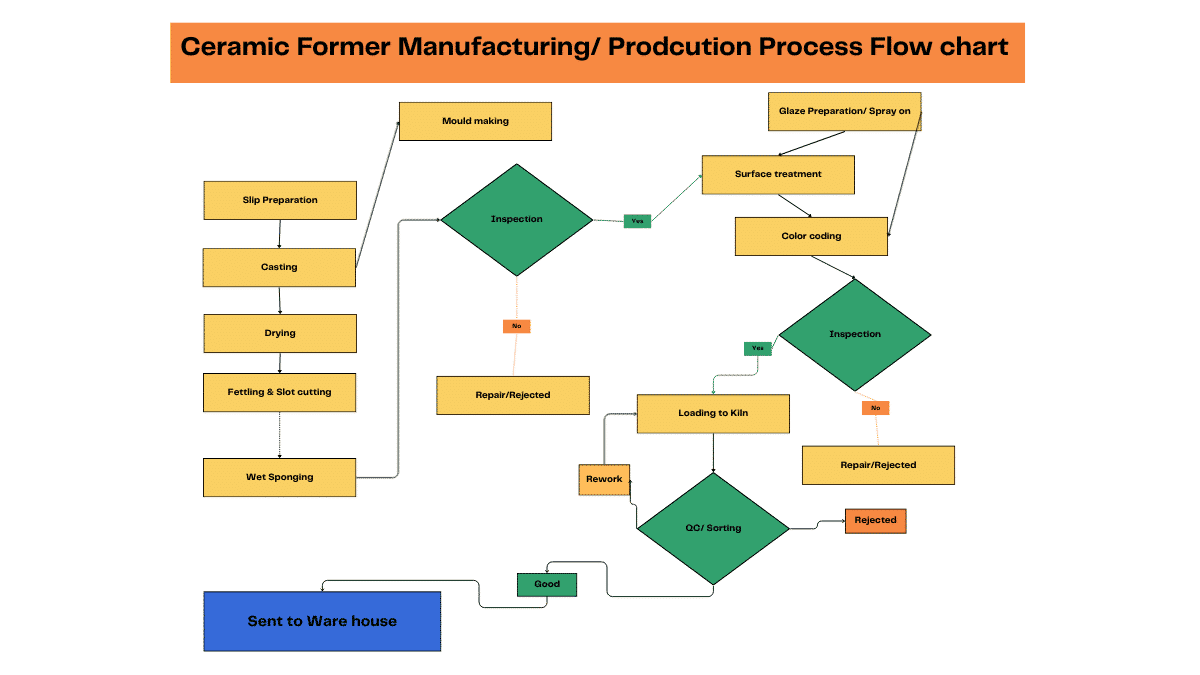

Manufacturing Process

The Ceramic formers are produced using traditional bench casting, may supported by simple conveyor automation for efficiency in large factories, small factories go for manual methods of production. Due to R&D and process improvement the quality of the ceramic formers improved lot in last 5 years especially after covid where the ceramic formers industry boomed and brought lot of investment to the industry. This made more metal former users to move to ceramic formers. Find Ceramic Formers manufacturing process

Global Productions:

Top level global producers of ceramic formers are Malaysia, China, and Thailand. and the production is spreading all around the world.

3 comments