Description

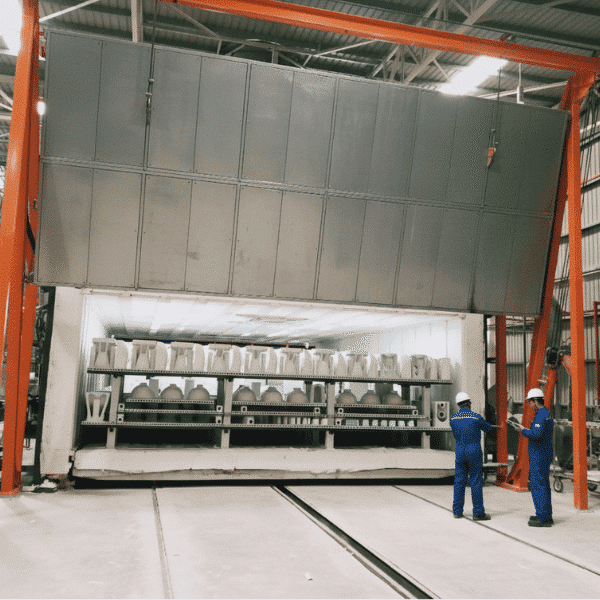

Customized Shuttle Kiln for Sanitaryware & Ceramics

Looking for sanitaryware shuttle kiln solution? Look no further. We specifically design our high-quality shuttle kilns for the sanitaryware industry. Built with durability and energy savings in mind, our kilns offer a high firing yield through uniform heating and low temperature variation. We are ready to provide complete customization to fulfill your production needs, temperature requirements, and product variations.

Key Features:

Peak Temperature: Up to 1250°C.

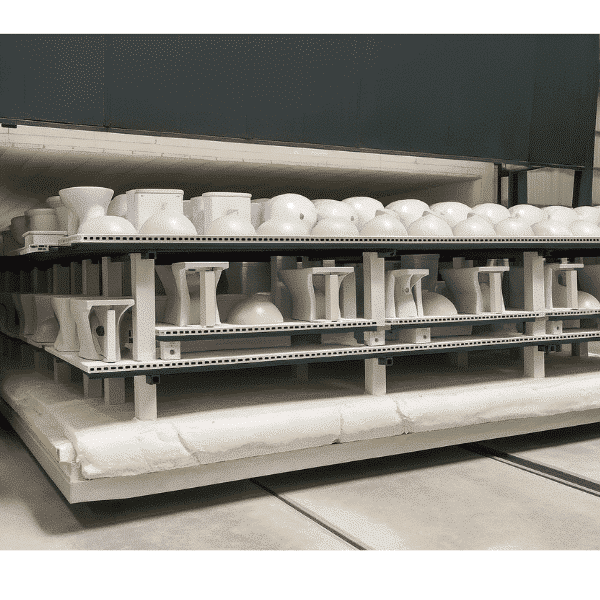

Kiln Size: 2 decks/3 decks/4 decks based on production design needs.

Energy Efficiency: insulated with low thermal mass fiber and new technology burners/PLC systems.

Uniform Firing: Zone-wise temperature control for low temperature variation between zones.

High Durability: High-strength materials are used for long-lasting kilns.

Kiln Car Options: Manual, semi-automatic, and fully automated kiln car movement using a pusher.

Fuel Options: Natural gas, LPG, and electricity. – Customers can choose any method they prefer.

Technical Specifications (options for customization):

Chamber Dimensions: Width 6–14 m | Height 3–6 m | Length 10–16 m

Firing Cycle Time: 14–36 hours (depending on product design)

Capacity: 300 to 800+ pieces per cycle (depending on product mix).

Control System: Fully automatic PLC with PC/touch-screen interface.

Why Choose Our Shuttle Kilns?

- Improved custom design for sanitaryware firing.

- Our team has more than 15 years of experience in sanitaryware kiln solutions.

- Our kilns are energy-efficient and require minimal maintenance.

- Complete solution from installation to firing cycle curve setting.