In this article, we will see detailed information about battery casting machine used in sanitaryware production. Battery casting is much advanced technology than the bench casting it reduces the space in production and increases the production speed. A lot of sanitaryware companies now upgrading their bench casting to battery casting for possible products. The battery casting investment pay back time is around 1 year. Implementing battery casting will take time around one months for existing bench casting products. The time is to change the required product model to adjust for battery casting setup. now sanitaryware production companies converting all washbasin moulds from bench casting and it saving more space and it very much protective. Battery casting models can be used to produce water closet and wall hung too.

Overview:

Battery casting is one type of casting which required less space for more moulds. In this battery casting the moulds are arranged one by one like batteries. In this casting the moulds are placed on the iron plates which are having bearing at the bottom. These bearings are used for free movements of moulds. These bearings are connected to tracks.

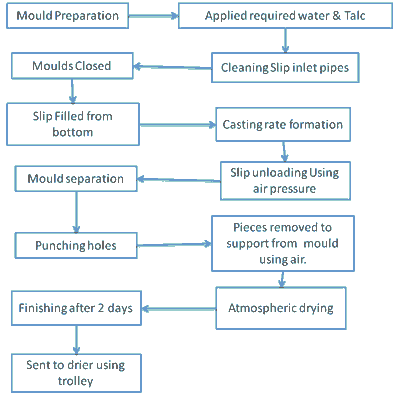

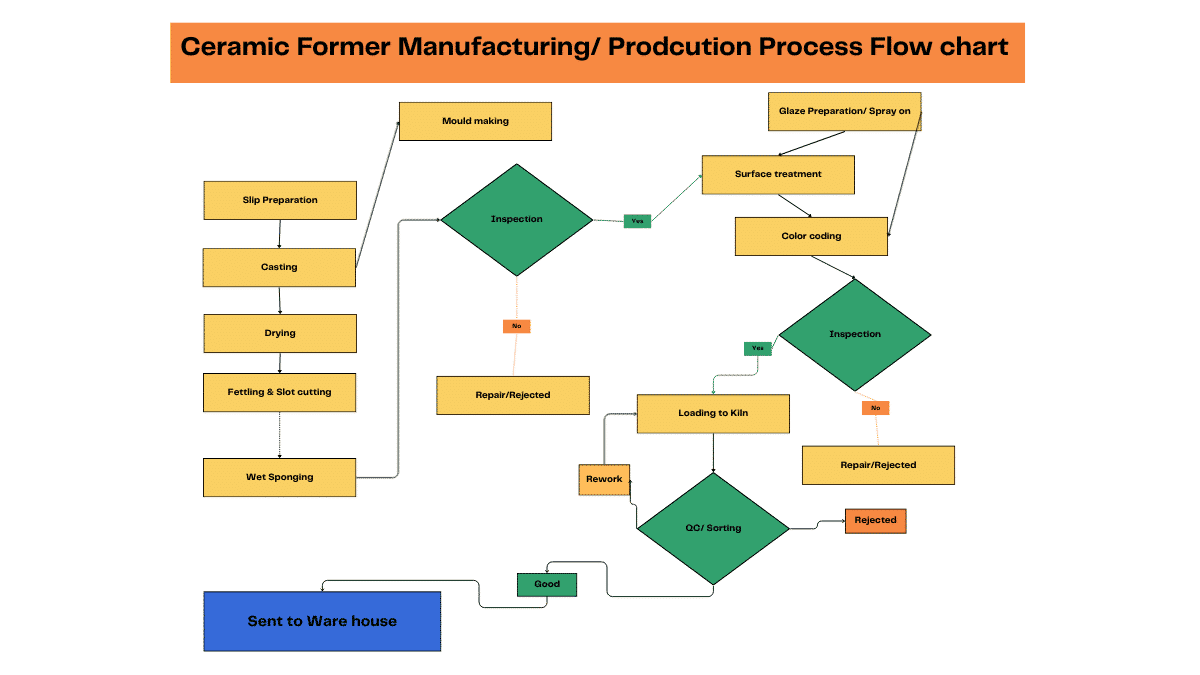

Casting Process in Battery casting:

There won’t be much difference from bench casting to battery casting. Only the mould handling and the slip is drained using air pressure whereas in bench casting slip will be drained only by gravity.

Mechanical parts of battery casting machine in sanitaryware:

Below are the parts of battery casting machine,

- Battery Casting Bench = Around 27 meters.

- Mould clamping device.

- Mould carrier with bearings.

- Guide pin with bearings.

- Trolleys: No of trolleys varies from according to the design of the product.

- PVC Slip Line.

- Ball Valve.

- PP Main Ball Valve.

- PVC Nipple.

- PVC Hose Nipple.

- Slip tank.

- Tank stand.

Battery casting machines can be used for pan items, washbasins, water closets, Traps and other simple sanitaryware products. Complex patterns like one piece toilet , Urinals are not suitable for battery casting.

A casting line can hold up to 60 big size washbasin moulds or 40 water closet or 180 small ‘P’ Traps or 70 Asian pans.

Advantages:

- High productivity (Nearly double) compared to traditional bench casting methods.

- Ease of mould handling as the mould need not be lifted and only need to be slided in the rail.

- Minimized the possibility of mould breakage and damages(chipping) that often happens in bench casting.

- Space required is very low compared to bench tradition casting.

- More than one product from a mould is possible for small/Accessories products like ‘P’ or ‘S’ traps.

- No need of special slip like High pressure casting machine for sanitaryware. Normal bench casting slip can be used.

Limitation:

- Producing complex patterns like one piece water closet are Much difficult.

- Switching from benching to Battery casting needs some design changes in mould.

Suppliers:

- We have mentioned some of the battery casting suppliers here, But we will try to include more. And we add soon the contact details of the battery casting suppliers of sanitaryware.

- Fortune Engineers.

- Anil Brothers.

- Tangshan Hexiang Industrial.

Conclusion:

I hope that I have provided enough information about sanitary ware battery casting. If you want to know anything more or share any of your thoughts please share it below in comment section. Share this article using below buttons on your favorite social media. After all, sharing is caring.

7 comments