Comprehensive Guide to Ball Clay: Properties, Composition, Processing, and Applications

Ball clay is a kaolinite-rich secondary clay known for its distinctive dark brown to black color, transitioning to white or light cream upon firing. This versatile clay, also referred to as plastic clay, contains major minerals such as kaolinite, mica, and quartz. In this guide, we’ll explore the properties, chemical formula, composition, testing methods, mining and processing, suppliers, and diverse applications of ball clays.

What is ball clay?

Ball clays are high-plasticity clays, characterized by fine particles and a chemical composition containing silica, iron, and titanium impurities. The name “ball clay” originated from the method of extracting it in spherical shapes.

Ball clays are characterized by higher plasticity, dry shrinkage, and dry strength as compared to china clays. They are chemically impure and often contain a large proportion of silica, iron, and titanium impurities.

Plasticity: Higher than China clays, resulting in increased green strength.

Chemical Impurities: Commonly includes silica, iron, and titanium.

Carbonaceous Matter: Influences physical properties and unfired strength but increases porosity after firing.

Ball clay properties:

The ball clay deposit is sedimentary and consists of numerous strata that frequently vary significantly in physical properties, although perhaps not much in chemical composition. Ball Clay is generally called Kaolin, that had been transported from the primary decomposed parent, or igneous rock, which were usually granite by nature, via glacial displacement, making It is a secondary clay, and in this process, it not only gains high organic impurities and iron contaminants, but the material also gets ground down into a finer particle size!

- Quality specifications of ball clay: Some relevant quality specifications for the ball and plastic clay are:

- Residue/Grit Content: ≤ 2.0 wt% on 45 microns (325 mesh) IS sieve.

- Coarse Particles: ~ 3.0 wt% finer than 25 microns.

- Fine Particles: ~ 70 wt% finer than 2 microns.

- Water Plasticity: ~ 34 wt%.

- Unfired Strength (MOR): ≥ 35.0 kgf/cm².

- Fe₂O₃ & TiO₂: Combined ≤ 2.75 wt%, individual constituents ≤ 1.5 wt%.

Physical properties of ball clay:

Main features include high plasticity due to fine particles, which gives high green strength for handling the product at the green stage. It requires much more deflocculant to achieve the required fluidity compared to china clay because of fine particles and organic impurities. Ball clay exhibits a higher green MOR compared to china clay, primarily due to the presence of more fine particles. Fired shrinkage is comparatively more due to high loss on ignition and particle size distribution.

- Green Modulus of Rupture: 65 kgf/cm².

- Water absorption after Firing: Around 12%

- pH value: From 6 to 8.

- % of Dry Shrinkage: 3 to 4%.

- % of fired shrinkage: 6% to 9%.

- Residue on 300 mesh: 1% to 5%.

- Casting rate: Comparatively low with china clay in slip conditions with the same fluidity, viscosity, and density.

- Drying time: Slow compared to china clay.

Chemical Formula & Composition of Ball Clay:

The chemical formula of ball clay is Al₂O₃. 2SiO₂. 2H₂O.

The chemical composition of ball clay varies very much from place to place, even from one lot to another.

| Mineral | Percentage |

|---|---|

| SiO₂ | 45% to 60% |

| Al₂O₃ | 25% to 35 % |

| MgO | 0.1% to 0.5% |

| TiO₂ | 0.5% to 2% |

| Fe₂O₃ | 0.50% to 1.5% |

| Cao | 0.1% to 0.5% |

| Na₂O | 0.1% to 0.6% |

| Loss of Ignition | Around 14% |

Ball Clay Processing:

Ball clays are sold directly from the mine without processing, other than the air-drying which may occur under favorable circumstances.

However, in some cases, ball clay is processed after mining to reduce/remove impurities.

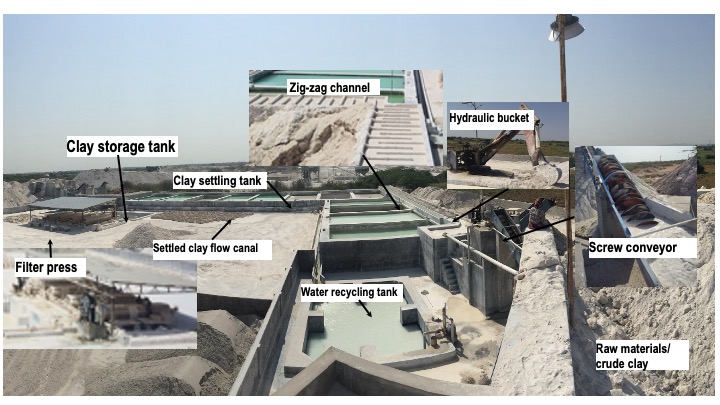

Steps in the Ball clay processing are,

- Mining: Extracted mechanically using a hydraulic backhoe or using a jet pump. Extracted clay is mixed with water.

- Sieving: Slurry passed through sieves up to 40 mesh and also passed through magnets to remove iron impurities.

- Settling: Clay particles settle through zig-zag settling. Water will be removed from the top.

- Filter Pressing: Slurry is fed into a filter press to form cake-state clay. This process reduces the water content in clay to around 18%.

- Drying & Packing: Cake clay is dried, weighed, and packed in different bags based on the customer requirement.

Single-ball clay is rarely used in manufacturing due to its varying properties. Two or more ball clays are mixed and used in the ceramic production process to maintain consistency.

Ball Clay Tests:

Following are some of the tests that are carried out in a laboratory where ball clay is used as a raw material in the production process.

Ball Clay Suppliers:

A list of global suppliers is provided for those seeking reliable sources of ball clay.

- Imerys Ceramics India Private Ltd.—India Address: Surya Arcade, 4th Floor, Begumpet, Hyderabad—500016, India. Contact No: 040-30586666, 30689851, 30689877, 30682266, 30689880, 30689880, 07702070088, 09959911833

- Kothari Clay Industries – Gujarat, India. Contact Person: Mr Chetan Kothari. Address: Mahalaxmi Street, Post Office, Thangadh–363530, Gujarat, India. Contact No: 09825393663, 02751-220263/220863. Fax: 02751-220263

- Ashvin Ceramics – India

- Mita Madencilik Ltd – Turkey Address : Eskisehir, Seyitgazi, Turkey, Zip Code: 2600 Contact Person: Takittin Erol Telephone: 90-252-3822744 Fax: 90-252-3824211

- Swastik Minerals – India

- Amarnath Industries—India Contact Person: Mr. Amarnath Jha Address: Behind Arya Samaj School, Rathkhana Colony, Bikaner–334001, Rajasthan, India. Contact No: 09414147777

Functions:

The major functions of the ball and plastic clays in ceramic bodies are

- Provide fine particles

- Higher plasticity and workability

- Higher dry and lower fired shrinkages

- Higher unfired strength

- Make ceramic bodies buff-burning, low-maturing, and less translucent due to the presence of higher impurities.

Uses of Ball Clay:

Raw material in sanitary ware production: Ball clay is an essential raw material in sanitaryware production due to its green strength. It provides the sanitaryware handling strength in the green stage. Around 30% were used in the composition of sanitaryware production.

Raw material in wall & floor tile production: Around 14% is used in floor and wall tile production to give better particle size distribution for better density and whiteness to the product.

Raw material in refractory production: Because of the plasticity property of the ball clays, it is used in the refractory brick production to impart shape to the product.

Raw material in ceramic clay pipe production: Due to the workability property, it is used in ceramic clay pipe production.

Raw material in electrical insulators: It is used in electrical insulator production to impart the insulation properties to the insulator.

Raw Material in Tableware Production: One of the raw materials for the production of tableware. It provides better shaping and green strength to the tableware product.

Used as filler & extender: Ball clay is used in industries other than ceramic for its binding properties. It is used as a filler in paint, fertilizer, etc.

Conclusion:

While this article covers a wide range of aspects related to ball clay, we acknowledge the potential for further refinements. If there are additional insights or information you’d like to contribute, please share your comments below.

Find more details about China clay here.

28 comments