A perfect formulation of ceramic formers body or slip ensures that the material meets all the requirements for both production process handling and final product performance. Before we discuss the formulation in detail, let us first look at the key properties expected from a ceramic hand former body or slip. We can divide the required properties stage-wise based on the process.

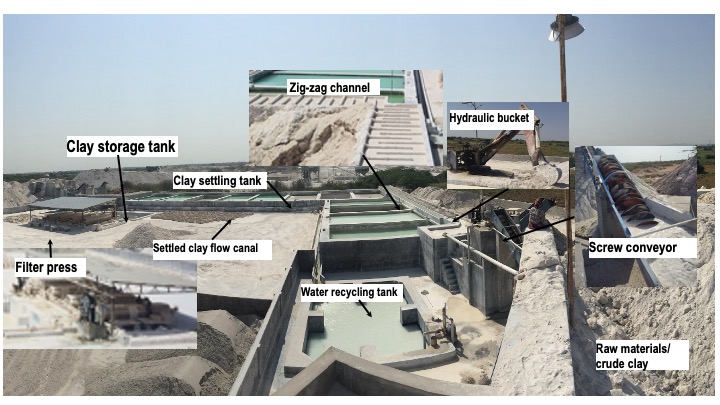

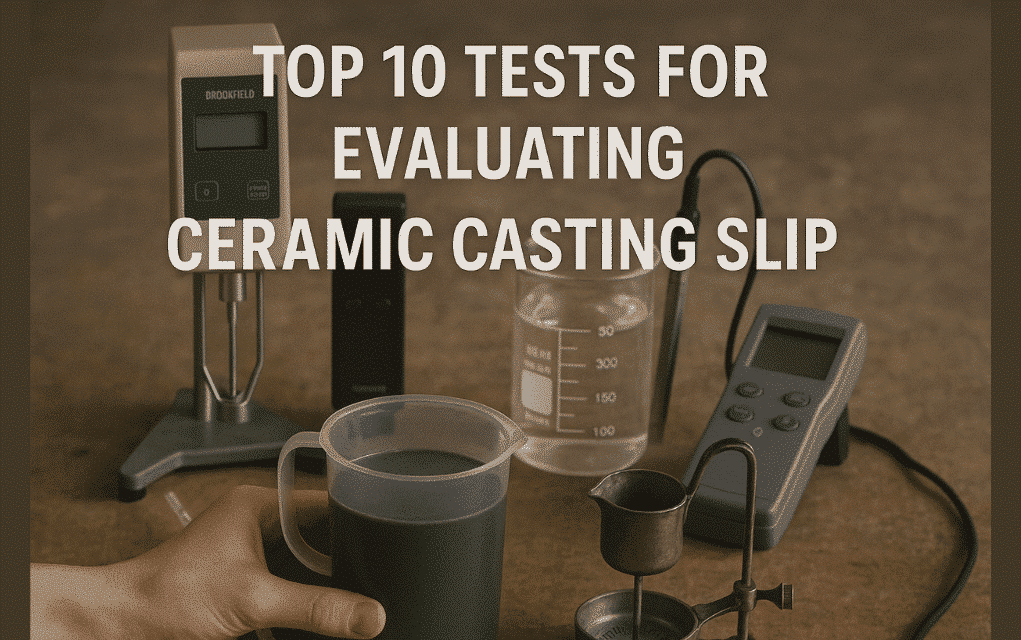

Slip Preparation:

During slip preparation, we expect the slip to require less deflocculant to achieve the expected flow / rheological properties, which helps the slip unload easily from the ball mill and the blunger. Better slaking property of raw materials helps in easier blunging and milling. Stable slip properties help prevent settling of non-plastic raw materials during storage and transportation through pipelines.

Casting:

During casting, the slip should provide enough cast rate to cast the piece at higher production rates based on the casting process. A manual casting process may take about 40 minutes including casting and unloading, while automatic casting may require a faster casting rate. So based on the casting process we have to formulate the body to get the required cast rate.

The thixotropy rate should be low so that unloading of the slip is effective without any slip remaining in the piece. This also helps in faster drying. So we are expecting a highly fluid slip, which comes mainly from clay raw materials. This helps avoid flow marks on the ceramic formers.

Faster drying helps form a harder wet body, enabling easier demoulding of pieces from the mould. And a high plastic body will ensure fewer drying cracks during the hardening process.

Handling:

High dry MOR property is required for better handling and in-process operation before firing. This property helps to reduce chipping, handling breakage, and knocks during sponging and inspection.

Firing:

The formulation needs to be fully vitrified during firing, which should achieve less than 0.5% water absorption at the set firing cycle. Good fired MOR, good whiteness and thermal shock resistance are expected from the body to fulfill the end user requirements. After firing, the body should be chemically inert so that the life of the former is extended during use.

Overall, the formulation should fulfill all the above properties, while remaining cost-effective for producing formers at the lowest possible production cost.

Raw Materials:

To achieve these properties of the body, we use four raw materials in the formulation. Each raw material brings its own advantages to the formulation and helps mitigate weaknesses of the others.

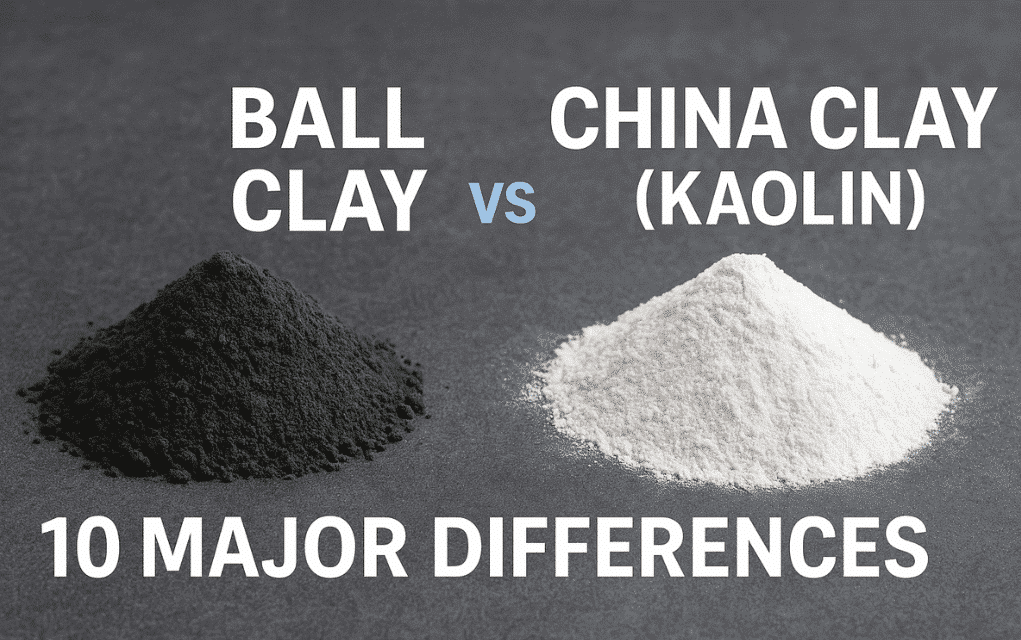

- Clay: (Ball clay, China clay): Ball clay and china clay are used to bring stability to the slip, Plasticity to the wet hand former body and handling strength to the body from casting to firing,

- Quartz: Quartz helps to increase the fired strength, better fusion (vitrification) with the flux to the body and drying properties of the body.

- Flux: (Nepheline syenite/ Potash / Soda Feldspar): Feldspar helps to vitrify the body at lower temperature, drying properties and also provides silica and alumina to the body.

- Calcined Alumina: Calcined alumina brings better fire strength (Fired MOR), chemical inertness and thermal shock resistance to the body.

Ceramic Hand former body formula:

Here is a typical Ceramic Former Body Formulation: This needs to be fine tuned based on the mineral strutcher of the raw material, process parameters and firing curve.

| Raw Material | Percentage |

|---|---|

| Ball clay | 15% -19% |

| China clay | 31% -35% |

| Flux (Feldspar) | 21% -25% |

| Calcined Alumina | 18% -22% |

| Quartz | 5% -8% |

We have covered Ceramic hand former Manufacturing process formulation in this article. Leave us comment if you want to know details/Any doubt on this topic.

Post Comment