The crude clay excavated from the ground consists of clay, sand, small stones, organic material, and other heavy minerals. The percentage of clay in the crude can be as low as 8%. The recovery of the clay varies based on the deposits. So a process is required to refine the crude clay. The levigation process is an effective way to refine the clay from the other materials.

The levigation process is one of the widely used methods and the primary method of refining the crude clay into clay. This process is also called by other names, like the setting process of clay. After the levigation process, the clay becomes usable in the tile, sanitaryware, electro porcelain, tableware, or any other ceramic industry with impurities less than a few percent.

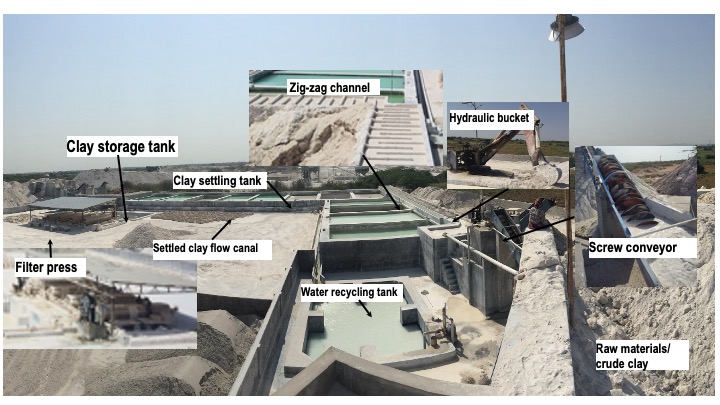

After the crude clay is excavated from the deposit, it is sorted to remove any large stones before being sent to the levigation process. The clay levigation process consists of 7 steps. Below are the steps followed in the levigation process in ceramic industries.

Blunging:

In the first step, the raw clay is mixed with water in a mixing tank known as a blunger. The aim is to turn solid clay lumps into a smooth, uniform clay slurry. High-speed blunging helps the crude clay disperse evenly and form the slurry faster. This blunging process is done batchwise. Once the blunging process is complete, the crude clay is ready for separation.

Separation:

Once the clay slurry is prepared, it is fed via a separator/screw conveyor. Multiple screen conveyors are employed to remove the coarser materials and lumps from the crude slurry. Most of the material separated from this process is sand. These sand particles are collected on the other side of the conveyor and sent for sand processing and particle size grading. The balance slurry is sent to the settling tank.

Settling Tank:

This continuous process involves sending the slurry to one side of the tank, allowing it to move slowly so that heavy particles settle at the bottom while finer clay particles are carried by the water to the opposite end of the tank. This separation is carried out by gravitational force. This This stage utilizes simple physics and gravity to purify the clay slurry.

Zigzag Channel:

This is where most of the clay refining will be collected. The clay slurry from the settling tank is passed through the zigzag channels. The length of the zigzag channel and the number of zigzags used vary depending on the yield percentage of clay extracted from the crude clay. If the crude clay contains more yield, the size of the zigzag channel will be smaller. Vice versa, if the crude clay contains more sand impurities, then more zigzag channels are required.

The principle of the zigzag channel is that heavy particles have more inertia and tend to resist changes in motion, which causes them to settle down faster. The fine particle of clay will be carried to the end of the zigzag channels. Once the slurry passes through the zigzag channel, it is sent to the settling tank.

Settling Tank:

After the zigzag channel, the slurry flows to a series of settling tanks for the final step in the process. The goal of this step is to let the smaller particles settle and get rid of the water on top. This step helps in two ways. One is that high-density slurry is collected at the bottom of the tank for an efficient filter press process, and organic impurities, dissolved impurities, and dust, which have less density than the water, will be removed from the water. The settled clay slurry is pumped from the bottom of the tank to the filter press for the next process.

Filtered Cake:

The slurry is pumped to a filter press for water removal and to bring the moisture content of the clay close to 18%. Once the filtration process is done, the clay cake is removed from the filter and moved for the drying process.

Drying:

The filtered cake is spread out on an open area for drying. Sunlight accelerates the drying process, and shaping the clay cake into noodle forms before drying further speeds up the drying process. The expected moisture content before breaking down the cake into smaller lumps is less than 10%. This natural drying process may take a minimum of 1-2 days. Recent technology accelerates the drying process by heating the clay while it is transformed from cake into noodle form.

Advantages of the Levigation Process:

- Simple equipment is required.

- The process is straightforward and requires minimal maintenance.

- Volume of production is high.

Disadvantages:

- This method requires more manpower compared to the hydrocyclone processing method for clay.

- Cost of operation is higher.

- A larger place is required for the process.

The clay levigation process is a straightforward process where not much control is required at each step. Because of the higher cost and other disadvantages, the clay processing industry is trying to slowly move to the hydrocyclone process for crude clay processing. This levigated clay is also further processed for specialized purposes. These processes are known as secondary clay processes, like calcination, spray drying, magnetization, decantation, etc.

Post Comment