Fire clay that is mined in the region of Thangadh, Gujarat is known as Than clay. This clay is widely used in Thangadh and Morbi ceramic factories (especially sanitaryware industry). This Than clay has high refractoriness, medium plasticity, and low fluidity.

Supplied Variants:

Than clay is supplied to the ceramic cluster industries in two forms. One is raw form which is mined and directly supplied to the industry. This clay is in dark black form and used in industry by milling in a ball mill to be used in the body formulation.

The second form is Grey or Washed Than clay. This Than clay is comparatively better than raw Than clay in terms of residue, flow properties, and MOR. Recovery may vary based on the deposit but normally recovery is between 70–80%.

Raw Than vs Washed than

| Crude Than Clay | Washed Than Clay |

|---|---|

| High silica content / Residue | Low residue / Removed during sieving |

| Low MOR | Comparatively high MOR |

| Low price. Starts from 500 INR/MT | Price starts from 1100 INR/MT |

Supplied Forms:

Than clay is supplied in 4 major forms,

- Pulverized.

- Powder.

- Cake

- Noodles.

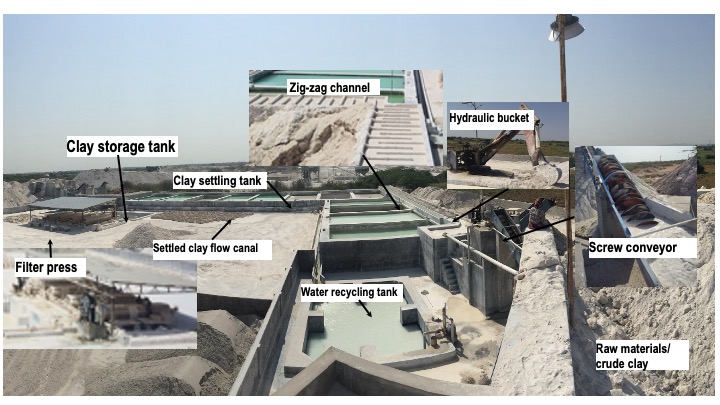

Manufacturing Process of Washed or Grey Than Clay:

Below is the simple process of washing Than clay:

- Blunging—Crude clay is mixed with water, and slurry is prepared.

- Sieving—Slurry is passed through multiple sieves to remove residues.

- Filter Press – Sieved slurry is pumped and pressed in the filter press to remove the water.

- Drying—The filter cake is removed from the filter press and dried in the open area to reduce moisture.

- Packing—After drying, the lumps are broken mechanically and then packed and loaded based on the supplier’s requirement.

Properties of Than Clay:

High silica content: 57–60%

Fluidity: Low fluid

L value = around 85

Pros of Than Clay:

- Than Clay is readily available near the Morbi cluster market.

- Low-price raw material.

Cons of Than Clay:

High-free silica causes dunting and delayed dunting it if it is not ground properly. Grinding increases the energy cost.

The high carbon content leads to bloating and black core issues in the high-thickness cast piece or fast-firing curves.

Low shrinkage occurs during firing, so it must be combined with other ball clay and china clay to compensate for the shrinkage values.

High deflocculant demand in casting slip production.

Unstable flow properties.

Conclusion:

Than clay can be used in certain percentages in the body to reduce cost, and to minimize defects, it should be moderated and mixed with good-quality clays.

Post Comment