Ceramic is everywhere in our life. We don’t notice these things because it became a part of our life. In this article, we are going to see all the types of ceramic we have.

Types of ceramics

Now we discuss the types of ceramics in detail. The main classification of ceramics are

- Traditional Ceramics

- Advanced Ceramics

Traditional Ceramics

Traditional ceramics are olden ceramics usually produced with naturally occurring raw materials such as clays, quartz, feldspar. Often, traditional ceramics are used to refer the ceramics in which the clay content exceeds 20 percent.

Traditional ceramics are further classified into following types based on their applications

- White wares

- Pottery

- Cement

- Insulators

- Refractories

- Monolithic Refractories

- Abrasives

- Tiles

- Glass

White wares

The name itself says whiteware! They are white in color , Results from the use of purer raw materials, and firing at high temperatures so thus giving sufficient strength and maturity. It may be glazed or unglazed depending upon the need of the customer. We can further classify the white wares into the following categories

- Porcelain

- Sanitary ware

- China ware

- Dinner ware or table ware

- Hotel china

Porcelain

Porcelain is a vitrified and a non porous ceramic ware. It also translucent in nature. It is usually made up with tri axial composition.

Composition

China clay – 60-67%

Potash feldspar -17-30%

Quartz -10-15%

A hard translucent ware usually of the triaxial composition, biscuit fired at a low temperature and glost fired at a high temperature or it may be once fired. The body is non porous and translucent

Physical properties

- Dense

- Non-Porous

- Translucent

- Hard

- Fine grained

Chemical properties

- Resitance to chemical attack

- High thermal shock resistance

The firing temperature of porcelain is usually high in order to achieve the vitrification. The firing range varies between 1100-1300.

Now we discuss the types of ceramics in detail. The main classification of ceramics are

- Traditional Ceramics

- Advanced Ceramics

Traditional Ceramics

Traditional ceramics are olden ceramics usually produced with naturally occurring raw materials such as clays, quartz, feldspar. Often, traditional ceramics are used to refer the ceramics in which the clay content exceeds 20 percent.

Traditional ceramics are further classified into following types based on their applications

- White wares

- Pottery

- Cement

- Insulators

- Refractories

- Monolithic Refractories

- Abrasives

- Tiles

- Glass

White wares

The name itself says whiteware! They are white in color , Results from the use of purer raw materials, and firing at high temperatures so thus giving sufficient strength and maturity. It may be glazed or unglazed depending upon the need of the customer. We can further classify the white wares into the following categories

- Porcelain

- Sanitary ware

- China ware

- Dinner ware or table ware

- Hotel china

Porcelain

Porcelain is a vitrified and a non porous ceramic ware. It also translucent in nature. It is usually made up with tri axial composition.

Composition:

China clay – 60-67%

Potash feldspar -17-30%

Quartz -10-15%

A hard translucent ware usually of the triaxial composition, biscuit fired at a low temperature and glost fired at a high temperature or it may be once fired. The body is non porous and translucent

Physical properties

- Dense

- Non-Porous

- Translucent

- Hard

- Fine grained

Chemical properties

- Resitance to chemical attack

- High thermal shock resistance

The firing temperature of porcelain is usually high in order to achieve the vitrification. The firing range varies between 1100-1300.

What is glaze?

A glaze is a thin shiny layer coating applied on the ceramic ware.

What is the advantage of glazing?

- Good appearance

- Smooth finish

- Easy to clean

- Long life

- High mechanical strength

- Resistance to scratching

- Resistant to chemical attack

If glazed – The porcelain ware is initially bisque fired at certain temperature around 1050 degree followed by coating of glaze in the ware. After glaze coating the ware is allowed for a glost firing in the temperature range of about 1300 degree.

If un glazed – The porcelain body is directly allowed for single firing around 1400 degree Celsius.

Based on temperature porcelain is classified into

- Hard porcelain (1330-1450)

- Soft porcelain (1200)

Based on the application Porcelain is classified in to

- Table ware porcelain

- Sanitary ware

- Chemical porcelain

- Electrical porcelain

Pottery

Pottery is a ceramic article usually made with clays, Pottery refers to olden ceramics. In traditional pottery the articles are made using pottery wheels for desired shapes and size. Here 12 tools are used for making an ceramic objects

Pottery can be made by Jiggering and Jollying process. In both of these process we can made only symmetrical objects.

Jiggering process:

By this process we can produce insulators, table wares, dinner wares and china dishes. In jiggering we use convex mould.

- Wet clay is placed inside a convex mould

- Batting is done. Batting means a forming tool is allowed to press the wet clay to provide a initial rough shape

- The jiggering tool is heated to produce a final shape by pressing the wet clay ( the purpose of heating the tool is to avoid the sticking of clay in the tool, thus we can achieve a good efficiency)

This process is applicable for fabrication of symmetrical flat wares like dinner plates and saucers

Jollying process

Jollying process is similar to that of jiggering process, instead of convex mould concave mould is used to make the articles.

Hollow ware like bowls, cups, pot, flower vases, jugs and other symmetrical objects can be produced by this method.

Classification of pottery

- Earthenware

- Stoneware

Earthenware

Earthenware mainly used for decorative purposes.

Compositions

Ball clay – 25 %

China clay – 29 %

Quartz -21 %

Feldspar -15%

Properties

- Can be easily chipped or broked

- Non vitrified

- Porous

- lustrous

- Non translucent

Firing Temperature

Bisque firing – 1000-1160 degree celsius

Glost firing – 950-1000 degree celsius

Stoneware

Stoneware is made with unrefined raw materials. It is a vitrified body with 5% porosity. Most of the stonewares are coloured due to the presence of impurities in the unrefined raw materials

Firing range: 1100-1200 degree Celsius

Why stoneware pipes is used in drainage construction instead of other wares?

If Metal pipes are used, it may get corroded, so there is a chances of sewage wastes passes through the surrounding area.

If we use Cement pipes, bacteria’s may passes through the tiny holes present in the cement pipes. It may tend to create some serious problems. So to avoid the above problems drainage is constructed using clays called stoneware.

Physical properties

- Dense

- Hard

Chemical properties

- Resistance to chemical attack

How to glaze the stone wares?

Since the size of the stone ware products is relatively bigger, we cannot apply glaze by usual methods

Salt Glazing

While firing the stoneware in furnace, salt is added to the ware around 800-900 degree Celsius, it immediately tends to vaporised and stick into the surface of the ware. Due to the vaporisation the temperature of the furnace decreases, so the temperature is increased and again the process is continued.

Based on compositions stone wares are classified into

- Chemical stoneware

- Stoneware sanitary ware

- Stoneware tableware

Applications:

They are used in the

- Construction purpose

- Sewage

- Drainage tanks

- Stoneware pipes

Usually they have longer life and high strength, so no need to replace often. Thus saving the capital, time and energy.

Sanitary ware

Sanitary ware is a type of ceramic ware, which is made into larger pieces. It plays an important role in our daily basis.

Example: Kitchen sinks, Bathtubs, Urinal Stalls, lavatories etc

Raw materials used

- Fireclays

- Quartz

- Kaolin

- Grog

- Saw dust

Firing Temperature

Firing temperature varies from 1200-1300 degree Celsius

Sanitary ware is further divided into

- Fireclay Sanitary ware

- Stoneware Sanitary ware

- Earthenware Sanitary ware

- Vitreous China Sanitary Ware

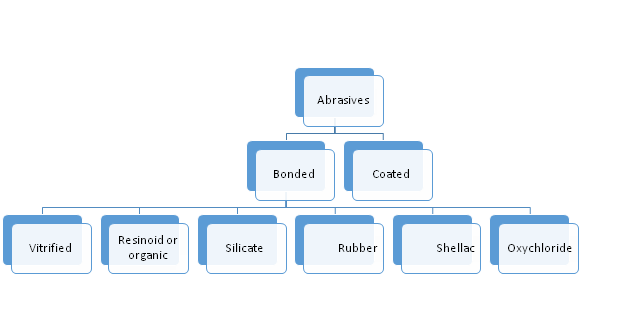

Abrasives

Abrasive is a material which is used for polishing, cutting grinding and to make a surface finish (for a smooth surface). Here rubbing action takes place between a hard material and soft material which leads to a removal of extra or unwanted particles or grains form the soft material by the friction.

Classification of abrasive grains

- Natural Abrasives

- Synthetic Abrasives

- Super Abrasives

Natural Abrasives

- Emery

- Flint

- Garnet

- Crocus

- Tripoli

- Pumice

- Diamond

- Pitamacous Earth

Synthetic Abrasives

- Diamond

- Silicon Carbide

- Alumina

- Alumina

- Crocus

Super Abrasives

- Diamond

- Alumina

- Cubic Boron Nitrate

Classification of abrasive

Bonded Abrasives

Bonded abrasives are usually the mixture of abrasive grains with bonding materials and filler. The binder are bonding agent may be in the form of liquid, solid or semi solid.

Example: Grinding Wheels

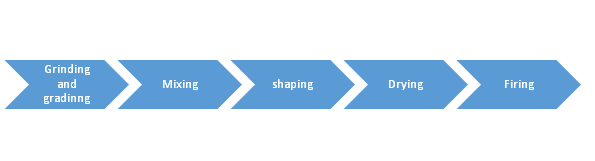

Manufacturing Process of Bonded Abrasives

Coated Abrasives

In Coated abrasives the grains are bonded to the substrate (or backing) with the help of adhesives. Commonly used backings are

- Paper

- Cloth

- Vulcanized Fiber

Requirement of Coated Abrasives

- It should be smooth enough for uniform adhesive coating

- Strong enough to withstand the grinding pressure

- Have to be flexible to use in contours

Manufacture Process of Coated Abrasives

Refractories

Generally, “refractory is defined as an ability of a material to withstand high temperature without undergoing any deformation”. It may be shaped or unshaped. Unshaped refractories are known as MONOLITH (refractories in powder form)

According to ASTM, the refractories are non-metallic materials having those chemical and physical properties that make them applicable of structure or components of system that are expose to environment about 1538 degree Celsius.

According to JIS, Refractories are shaped materials that are durable at high temperature about 1500 degree Celsius and unshaped materials and insulating fire brick with a service temperature of about 1800 degree Celsius.

Now we can see the classification of refractories.

Physical classification

- Shaped g.: Bricks

- Unshaped eg: Monolith

- Fibrous eg: A refractory is made into a fibre

Chemical Classification

- Oxides eg: Al2o3, Mgo, Sio2, 3Al2o3.2sio2.

- Non oxides eg: Si3N4, Sic, Al4N

- Composites eg: Mgo.C, Sic.C, Al2o3.Sic

Chemical Behaviour

- Acidic refractories eg: Sio2, Fireclay, Mullite

- Basic refractories eg: Dolomite, Mgo, Forsterite

- Neutral refractories eg: Cr2o3, C, highly pure Al2o3.

Thermal Classification

- Normal Refractories – 1580-1780 degree Celsius

- High temperature refractories – 1780-200 degree Celsius

- Super refractories – more than 2000 degree Celsius

Refractories has a great impact in the field of ceramics

General refractory manufacturing process

Properties to be tested for refractories

Physical properties

- Density

- Porosity

- Apparent porosity

- Bulk density

- Cold crushing strength

- Modules of rupture

- Microstructure

- wear

Thermal properties

- Thermal conductivity

- Thermal expansion

- Thermal shock resistance

- Pyrometric cone equivalent

- Permanent linear change

- Reversible thermal expansion

- Hot modulus of rupture

- Refractoriness under load

Chemical properties

- Hydration resistance

- Corrosion resistance

- Carbon mono oxide resistance

Tiles

Now a day’s tiles play a major role in the field of construction. Tiles are durable, Odourless, hygienic, fireproof, water resistant, chemical resistant, heat resistant, it has long lifespan, easy to install and even cost effective too, this is the main reasons for increasing usage of tiles in residential as well as in commercial areas. Tiles are available in rectangular and square shape. They are available in different colours, patterns and textures.

All tiles are ceramic tiles only but they are differentiated as ceramic tiles and vitrified tiles ( porcelain tiles which has nearly zero porosity)

Tiles may be in the form of

- Mosaics

- Marbles

- Sandstone

- Porcelain

- Quarry tiles

Depends on the usage the tiles are classified into

- Floor tiles

- Wall tiles

- Terracotta tiles

Floor Tiles

Floor tiles are usually dense, vitrified (nearly zero porosity, zero water absorption) and stronger, this is why because it should provide a necessary friction for us to walk if not we may slip down. So when compare to wall tiles, floor tiles should have zero porosity, more load bearing capacity and high strength in order to provide a good life span. They are available in various types of finishes such as glossy, matt, antiskid, high definition, textured, scratch free etc..,

Raw materials used:

- Stoneware clay

- Ball clay

- China Clay

- Cornwall stone

- Mica

- Feldspar

- Grog

It may be glazed or unglazed

Wall Tiles

In the case of wall tiles, it is not completely vitrified! It porous, its water absorption is nearly 10% and mostly used for decoration purpose. It can be made in to different shape, size and based on the specific finishes such as wood, rustic, metallic and stone etc.., and may be glossy or matt finish or it may be glazed or unglazed depending upon the requirement of the customers. Most of the time wall tiles are glazed with different colorants to provide a good decorative look. These tiles are suitable for internal and external wall applications

Raw material used:

This is similar to that of floor tiles

- China Clay

- Ball clay

- Flint

- Cornish stone etc

Terracota tiles

High graded fire clay is used to manufacture these types of tiles

Glass

A major [simple_tooltip content=’A glass is a amorphous material( non- crystalline)’]glass[/simple_tooltip] former is silica sand, when silica is heated to 1713 degree Celsius it gets melts. When the melt is subjected to a sudden cooling glass is formed. This is because we are not giving sufficient time for the formation of crystal, so atoms are randomly arranged and lead to the formation of glass. You can find the glass bottle manufacturing process.

Types of glass

Soda lime glass

Borosilicate glass

Potash lime glass

Potash lead glass

Common glass

Special glass

Mehanism of glass formation

- Nucleation

- Growth

Raw materials used:

- Silica Sand

- Limestone

- Feldspar

- Nepheline Syneite

- Borate materials

- Gypsum

- Cullet

- Colorants

- Fining agent

Advanced Ceramics

Ceramics are considered to be a pottery, refractory bricks, glasses, cements and abrasives! Not at all! Its usage is more than that. The last few decades have seen the development of ceramics in various areas and those developments in other words known as advanced ceramics.

Advanced Ceramic is an inorganic, non-metallic, basically crystalline material of rigorously controlled composition( control in grain size and shape,phase distributions and porosity) and manufactured with detailed regulation from highly refined and characterised raw materials giving precisely specified attributes.

Advanced ceramics are also known as technical ceramics or special ceramics or high performance ceramics. They are meant for extreme condition withstanding applications. For instance highly resistant to temperature, melting, wear, corrosion etc..,

They provide high electrical, thermal, dielectric, ferroelectric, piezoelectric, ferromagnetic, electronic, semiconducting, superconducting, ionic, electro-optical properties which hatch their use in wide range of industries.

Unlike traditional ceramics it need high pure raw materials some time a fine chemicals. It is mostly non-oxides.

Some of the advanced ceramic materials are

- Silicon Carbide

- Silicon Nitride

- Alumina

- Zirconia etc

Each with their own special characteristics and properties, which is highly efficient and economic. Conventional ceramics are processed by extrusion, slip casting, pressing, jiggering, jollying, drawing, rolling etc, where advanced ceramics are processed by hot pressing, battery casting and pressure casting etc,.

Traditional Ceramic vs Advanced Ceramics

Traditional Ceramics Advanced Ceramics Raw Materials : Naturally occurring raw materials Raw Materials: Beneficiated raw materials and synthetic Processing: i. Casting (slip)

ii. Extrusion (plastic mass)

iii. Pressing (powder)

Processing: i. Hot pressing

ii. Battery Casting

iii. Pressure Casting

Applications: Mostly house hold applications.

Applications: Extreme condition withstanding applications. Eg; aircraft application

Conclusion

We have covered a glimps of types of ceramics. Any concern please leave a comment below.

Wow..this is what i have searched for! Thanks a lot

Wow.. It was just amazing for a fresher to understand.. Excellent work.. Keep it up..

Interesting!!!!.. It’s nice to see from a student thinking about each and every steps in manufacturing process… Expecting more topics from the younger one!!!

Thank you so much

Thank u….